How IoT is Revolutionizing Industrial Automation

5 min read

Summary:

IoT technology is revolutionizing industrial automation, offering significant benefits such as predictive maintenance, real-time monitoring, and autonomous control systems. However, challenges like security and privacy concerns, integration with legacy systems, and workforce training need to be addressed for successful implementation. Innoboost is at the forefront of this transformation, as we provide holistic solutions that help businesses overcome these challenges and fully harness the power of IoT in their operations. As IoT continues to evolve, it is expected to play an increasingly important role in the future of manufacturing, shaping the way companies compete in the global marketplace.

The revolution has already begun

The Internet of Things (IoT) has made a significant impact across various industries, with the manufacturing sector being one of the most affected. Industrial automation, a vital aspect of modern manufacturing processes, is undergoing a massive transformation due to the integration of IoT technology. In this comprehensive blog, we will examine the numerous ways IoT is revolutionizing industrial automation, including predictive maintenance, real-time monitoring, autonomous control systems, and more. We will also discuss the challenges and considerations associated with implementing IoT in industrial automation while considering the future of this incredible technology.

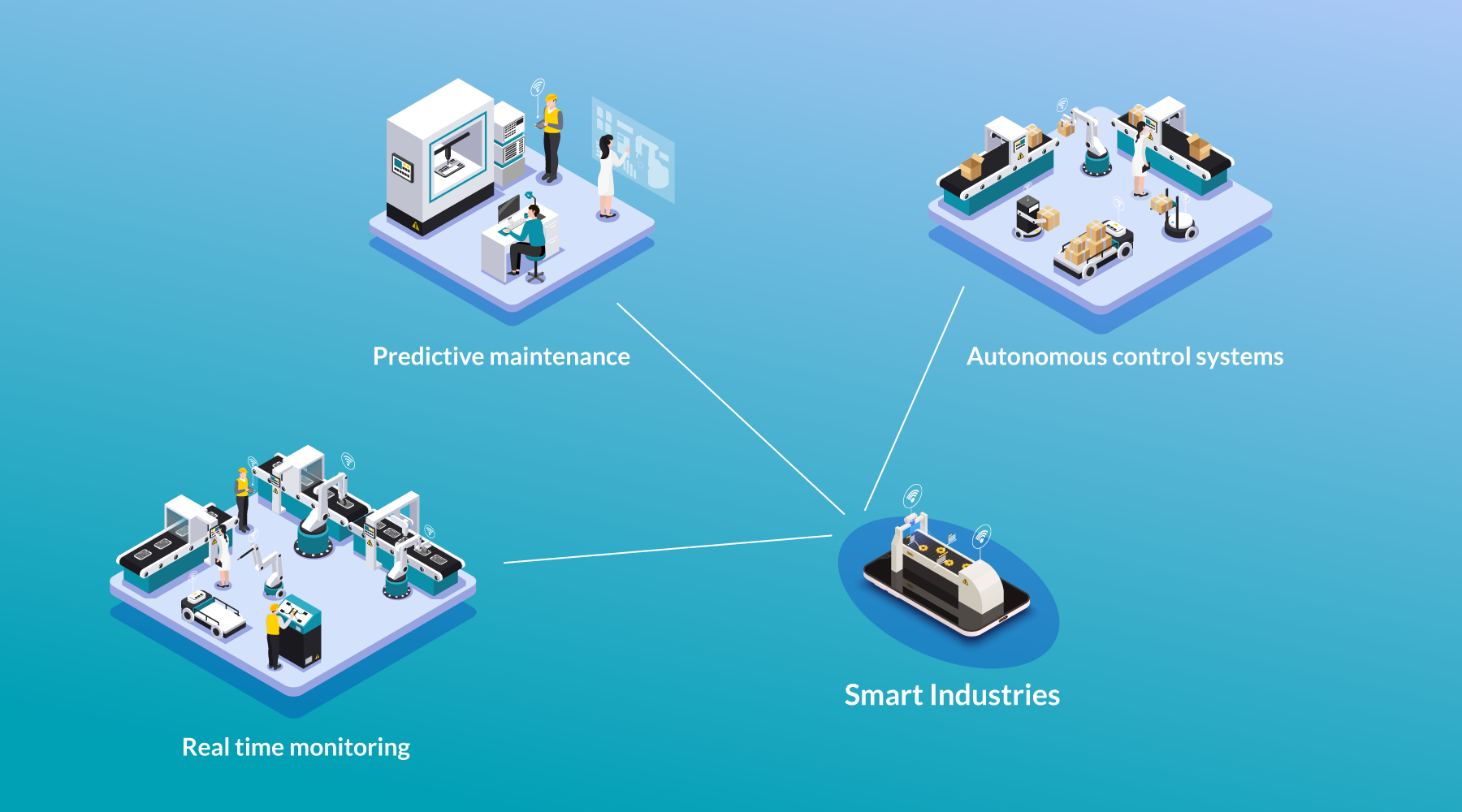

To start, here are 3 crucial contributions of IoT technology that have completely transformed the industry:

Predictive Maintenance

One of the most substantial benefits of IoT in industrial automation is predictive maintenance. By utilizing IoT sensors to collect data from equipment and machinery, manufacturers can monitor and analyze the performance of their assets. The information they get from this enables them to identify potential issues before they become critical, reducing downtime and minimizing repair costs.

Benefits of Predictive Maintenance

Reduced downtime: Proactively addressing potential problems before they escalate helps manufacturers minimize unscheduled maintenance time, increasing overall productivity.

Improved efficiency: Predictive maintenance optimizes equipment performance, leading to higher productivity and efficiency in the manufacturing process.

Extended equipment lifespan: Early detection and resolution of wear and tear can prolong the life of machinery and decrease replacement expenses.

Key Predictive Maintenance Technologies

Vibration analysis: Analyzing the vibration patterns of equipment can help identify imbalances, misalignments, and other issues that may lead to equipment failure.

Infrared thermography: This technology uses thermal imaging to detect temperature anomalies, indicating potential equipment problems such as overheating or insulation issues.

Oil analysis: Regularly analyzing the oil in machinery can reveal contamination, wear particles, and other signs of impending equipment failure.

Real-Time Monitoring

IoT technology enables real-time monitoring of manufacturing processes, providing manufacturers with up-to-date information on the performance of their assets. This data can be used to optimize processes, streamline operations, and ultimately improve overall efficiency.

Advantages of Real-Time Monitoring

Enhanced visibility: Real-time monitoring offers manufacturers a transparent view of their operations, allowing them to identify inefficiencies and areas for improvement.

Improved decision-making: Access to real-time data enables manufacturers to make informed decisions that optimize their processes and maximize output.

Increased safety: IoT helps identify potential safety hazards, allowing manufacturers to address them before they pose a risk to employees.

Real-Time Monitoring Applications

Production line monitoring: IoT sensors can track the performance of individual production line components, allowing manufacturers to identify bottlenecks and optimize throughput.

Energy management: Monitoring energy consumption in real-time can help manufacturers identify opportunities for energy savings and implement more efficient processes.

Environmental monitoring: IoT devices can measure temperature, humidity, and other environmental factors, enabling manufacturers to maintain optimal conditions for production.

Autonomous Control Systems

The integration of IoT technology in industrial automation has paved the way for developing of autonomous control systems. These systems can operate with minimal human intervention, using sensors, actuators, and artificial intelligence to control processes and make decisions based on real-time data.

The Impact of Autonomous Control Systems

Increased operational efficiency: Autonomous systems can optimize processes, reduce waste, and maximize output.

Enhanced safety: Autonomous control systems can help create a safer work environment by minimizing human involvement in potentially hazardous processes.

Greater flexibility: Autonomous systems can quickly adapt to changes in the production process, allowing manufacturers to respond to fluctuations in demand more effectively.

Examples of Autonomous Control Systems in industrial automation

Robotics: Advanced robotic systems integrated with IoT technology can perform complex tasks with precision and accuracy, reducing the need for manual labor in manufacturing processes.

Automated guided vehicles (AGVs): IoT-enabled AGVs can autonomously transport materials and products within a manufacturing facility, improving material handling efficiency and reducing human intervention.

Smart conveyor systems: IoT-connected conveyor systems can automatically adjust their speed and direction based on real-time production requirements, optimizing throughput and minimizing downtime.

Challenges and Considerations

IoT technology offers numerous benefits for industrial automation. However, it also presents some challenges and considerations that we, as developers of this technology, and manufacturers, must address when implementing these systems. Luckily, as a company that embraces a holistic approach to data lifecycle (of which IoT is just a part), we’re in a unique position that allows us to address and overcome these challenges during the development process itself. Some of those challenges are:

Security and Privacy Concerns

IoT devices can be vulnerable to cyberattacks, so manufacturers must prioritize the security of their systems. This includes implementing strong encryption, securing data storage, and regularly updating software to address potential vulnerabilities.

Integration with Legacy Systems

Integrating IoT technology with existing equipment and infrastructure can be complex and costly. Therefore, manufacturers must carefully consider the feasibility and return on investment before undertaking such projects, as it might take months and years to develop and optimize properly. However, once it’s up and running, the improvements and benefits of IoT implementation outweigh any financial or logistical constraints and costs.

Workforce Training

As IoT technology becomes more prevalent in industrial automation, manufacturers must invest in training their workforce to understand and utilize these new systems effectively.

Scalability and interoperability

Manufacturers should ensure their IoT solutions are scalable and can easily integrate with other systems and devices in their facility. That’s why we work closely with our clients to help them seamlessly transition from their old business model to a new, IoT-supported one. With this, we help companies maintain a flexible and adaptable manufacturing environment as their IoT infrastructure grows and evolves.

The Future of IoT in Industrial Automation

As we continue to improve and develop IoT technology, we can already see it playing an increasingly important role in industrial automation. The following trends are expected to shape the future of IoT in the manufacturing sector:

Edge Computing

Edge computing, which involves processing data closer to the source, can help reduce latency and improve real-time decision-making in IoT-based industrial automation systems.

Digital Twins

Digital twins, or virtual replicas of physical assets, can help manufacturers simulate and optimize their production processes, enabling them to make more informed decisions and improve overall efficiency.

5G Connectivity

The rollout of 5G networks will provide faster and more reliable connectivity for IoT devices, enhancing the performance and capabilities of industrial automation systems.

Conclusion

IoT technology is revolutionizing industrial automation, offering manufacturers numerous benefits such as predictive maintenance, real-time monitoring, and autonomous control systems. However, implementing IoT in industrial automation also presents challenges, including security and privacy concerns, integration with legacy systems, and workforce training. As IoT technology continues to evolve and advance, it is expected to play an increasingly important role in the future of manufacturing, shaping the way companies operate and compete in the global marketplace.

Our AnotherTrack and AnotherGateway products can help you implement real-time monitoring, predictive maintenance and autonomous control while reducing downtime, improving your operational efficiency and safety, and allowing you to make better decisions for your business.

Additionally, our expertise with Unity allows us to build digital twins that will elevate your approach to simulation, integration, testing, monitoring, and maintenance.

Contact us to schedule a meeting and learn more about how IoT can help your business.

You may also like…

Empower Your Workforce with Personalized AI Assistants

5 min readSummary In today’s rapidly evolving digital landscape, organizations are under constant pressure to optimize their workflows, improve efficiency, and reduce operational costs. As traditional automation tools struggle to keep pace, the next generation of...

Strengthening Your Enterprise Security with IBM QRadar: The Next Step in Threat Protection

5 min readSummary In a world where cyberattacks are becoming more frequent and complex, businesses need robust solutions to stay ahead of emerging threats. That’s where IBM QRadar comes in. Whether you’re managing a large enterprise or scaling your IT infrastructure,...

InnoBoost’s Blueprint for Seamless AI Integration

4 min readSummary Implementing artificial intelligence (AI) has quickly become a central focus for almost every company. They, too, want the piece of the cake, to integrate it, to reap its sweet rewards through enhanced productivity, reduced costs, and greater profit....